INDUSTRIAL 3D PRINTING - UNLIMITED PROCESS-RELIABLE PRODUCTION OF COMPONENTS MADE OF HIGH-PERFORMANCE THERMOPLASTICS

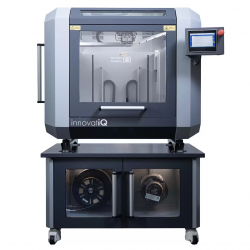

The TiQ 5 is the optimal system solution for the additive manufacturing of large functional parts. Unique Smart Functions ensure intuitive and user friendly use of the complex possibilities offered by additive manufacturing. Equipped with a build area heater and a water-cooled dual-lift print head, the TiQ 5 enables the process-reliable production of components made of a wide range of materials, in particular high-performance thermoplastics. Whether it’s a case of one-off production, large prototypes or industrial manufacturing – the TiQ 5 is the perfect choice every time.

APPLICATIONS IN INDUSTRY AND PRODUCTION

Components with specific technical properties:

Whether you require UV resistance, heat resistance, fibrereinforced or coloured materials; whether it involves series parts, prototypes or operating and auxiliary materials: Thanks to its open material platform, the TiQ 5 is always the perfect addition to your production line

Components with complex geometries:

Freedom of form requires a new way of thinking. Create added value for your customers with new designs. The TiQ 5 can master complex geometries with water-soluble support materials. This makes components more cost-effective – even with a batch size of 1.

Components for large tasks:

With its chamber volume of up to 90 litres, the TiQ 5 represents the benchmark in its class. Whether you have one large component or multiple small ones – you can deliver additively manufactured functional parts at the touch of a button and speed up your time to market.

Choice of possible materials with the TiQ 5

ABS: Most widely-used 3D filament material due to its versatility and good processability.

PA, PA-CF/GF: Heat-resistant material in industrial quality, enables the production of components with excellent mechanical, chemical and thermal properties.

PP*: Food-safe - certified to DIN EN ISO 10993-5 for biological safety.

Support material – water-soluble: Enables the printing of complex geometries. The support material offers excellent adhesion with the primary material and can be easily dissolved in a warm water bath.

PC*: High heat-resistance and excellent mechanical properties, enabling printing of highstrength functional parts.

ASA: Perfect for outdoor use due to its UV and weather resistance.

PET-G/C: Chemical resistance to water, acids, alkalis and alcohols.

TPU 95 Shore (A): Provides for flexible components, with some chemical resistance.

TiQ 5 – SIMPLE, RELIABLE, ADDITIVE

GestiQ Pro, the new HMI from innovatiQ

The TiQ 5 is equipped with the new industrial controller GestiQ Pro, which is operated via a large touch screen display. GestiQ Pro supports the operator with built-in shortcut keys. Everyday usage of the TiQ 5 becomes child’s play, with the operator having sight of all relevant parameters – even remotely.

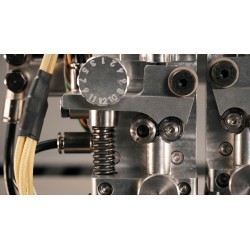

SmartFunctions - smarter with the TiQ 5

The SmartSpeed anti-slip controller and the SmartTrack intelligent filament tracking system ensure maximum process reliability in additive manufacturing.The TiQ 5 uses these systems to adjust its print speed to the capacity limit in an intelligent and dynamic way. You are guaranteed reliable achievement of your goals every time, at maximum conveying and printing speed.

Ergonomics and accessibility – the operator’s choice

With perfect ergonomic access and operating noise levels of less than 70 dB(A), the TiQ 5 is easy to use on a daily basis. The maintenance-friendly operating concept allows quick access to all technical components, thus reducing operating costs.

Laser levelling – minimal set-up time

The laser-assisted system levelling of the 6 mm thick glassceramic build plate is carried out automatically via the servomotors below. Time-consuming adjustments are now a thing of the past. Faster start-up, reliable achievement of your goals – all resulting in increased efficiency.

TECHNICAL DATA FOR TiQ 5

* Restrictions in the case of large-scale geometries

** Deviations depending on equipment/material/process

You might also like